Our facilities

We work closely with our customers to create tailor-made machinery and equipment, designed to meet specific needs.

We offer a wide range of solutions, from universal machines to fully automated production lines.

Production Capacity:

Systems built by us:

Universal stretch bending machines

Our CNC machines offer exceptionally precise and repeatable bending performance for a wide range of profiles with dedicated sections thanks to the multiple controlled axes.

Advanced technology ensures flexibility in production and allows us to adapt the power of our bending machines to the specific needs of each project, even for complex structural components, making them versatile for any type of sector.

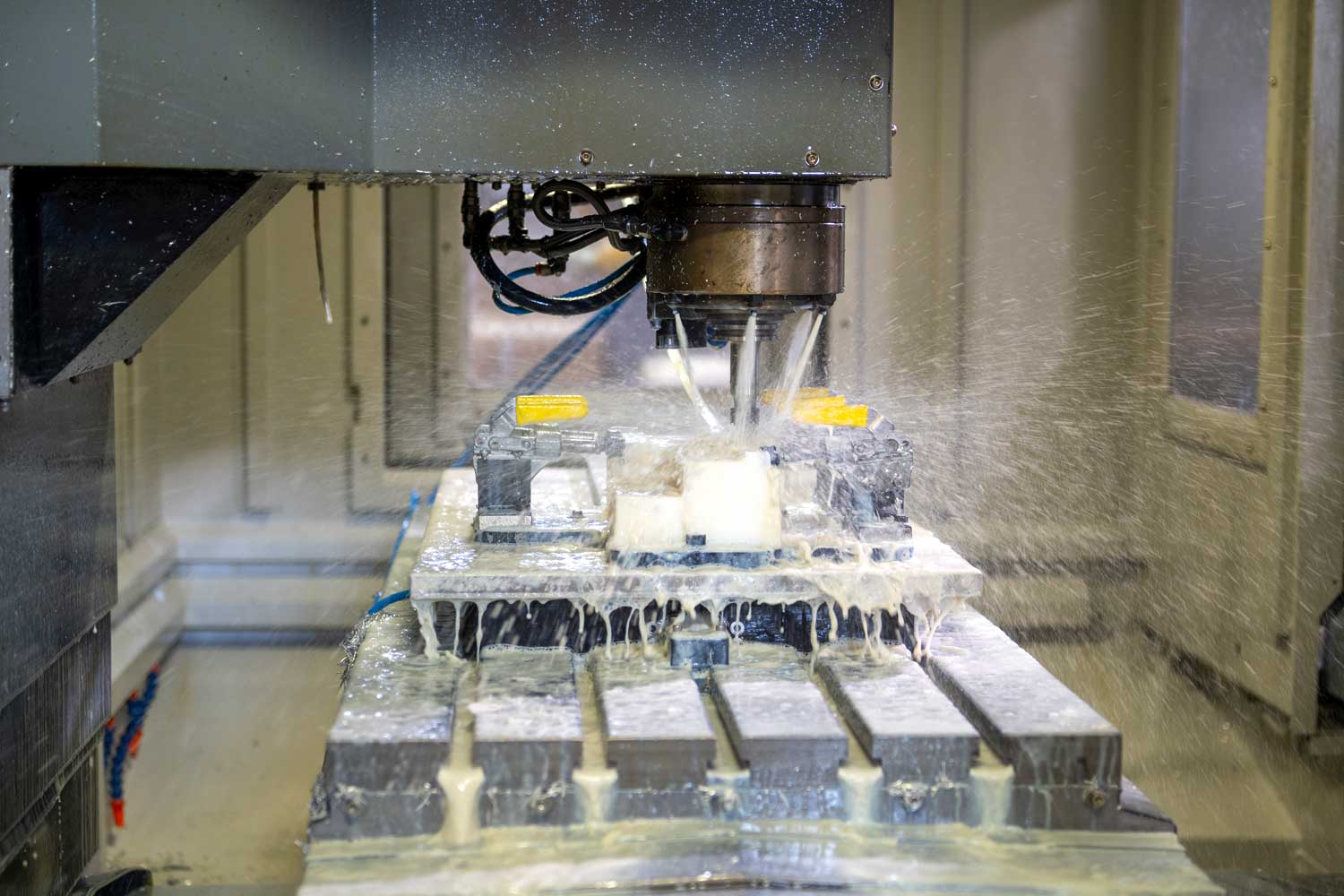

Universal milling machines

The modular milling machines we use are ideal for precision machining on various models.

With a process speed of up to 30 meters per minute and a spindle rotation of up to 24.000 rpm, these machines are perfect for milling operations on aesthetic and structural components.

Automated transfers

Our systems with multiple loading, processing and unloading stations guarantee high automation, productivity and space optimization.

They offer excellent accessibility to work units, reducing labour costs and ensuring high-quality performance.

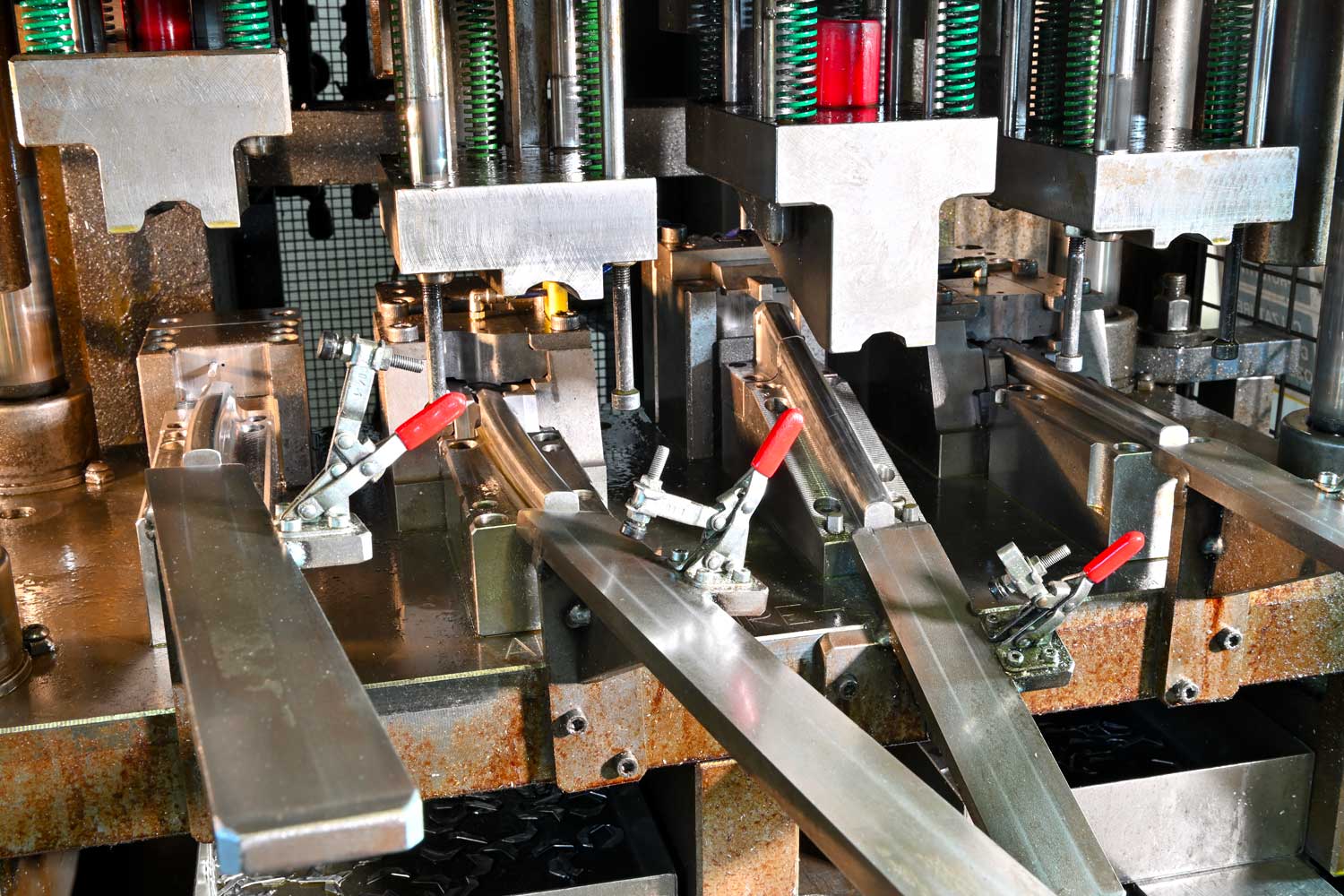

Moulds and mechanical presses

OMCM has 7 mechanical presses with capacities from 25 to 250 tons, perfect for stamping, cutting, bending and drawing operations.

We specialize in the production of block and progressive dies, supported by automatic feeders and unwinders for strips.

Bending tools

Our tools, characterized by speed of assembly and disassembly, are equipped with an automatic equipment recognition system, with a rapid CNC setup.

This allows for high precision and quality results, both functional and aesthetic, even on complex mouldings.

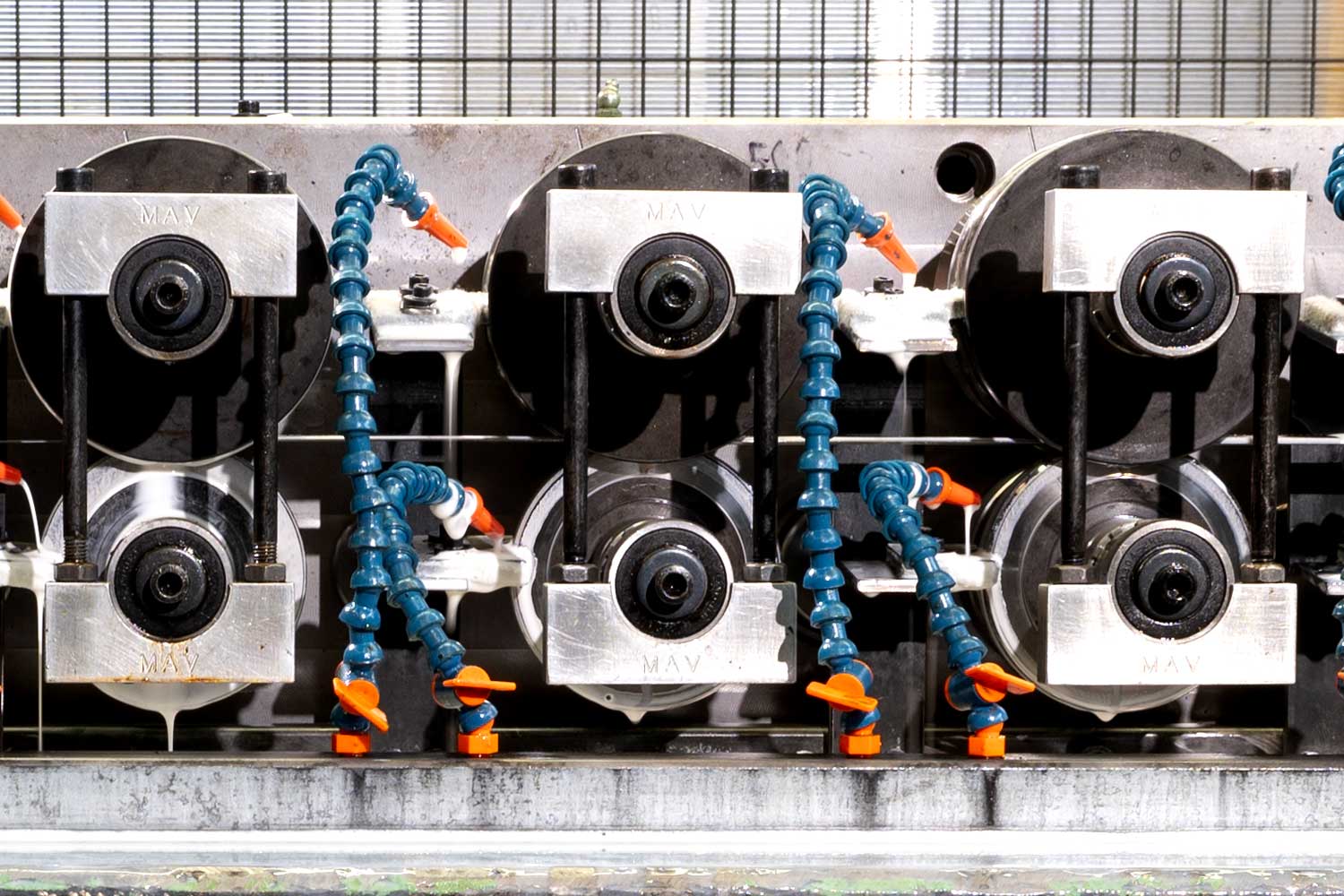

Roll forming and roller systems

Our roll forming systems enable the production of complex profiles with high precision and repeatability.

Thanks to modular systems and automated settings, we can work with different materials, optimising times and reducing waste.

The integration with CNC technologies and control sensors ensures the highest quality of the finished product, making the process efficient and versatile for multiple industrial sectors.

The solution to your needs.

Discover our machines and find the one that best suits your needs.

Contact us for a personalized consultation.